In today’s world, where fuel efficiency and environmental compliance are more important than ever, maintaining your engine’s cleanliness is critical. One of the most common yet often ignored causes of engine inefficiency and pollution is carbon buildup. This invisible enemy leads to engine knocking, reduced performance, increased fuel consumption, and higher emissions. Fortunately, there’s a practical solution: Carbon Remover.

Carbon Remover is a specialized chemical product designed to dissolve stubborn carbon deposits from critical engine components. By keeping these areas clean, you not only prevent damage and extend your engine’s life but also significantly reduce harmful emissions. This article will help you understand how knocking occurs, where carbon accumulates, and how routine use of Carbon Remover can help optimize performance while ensuring compliance with environmental standards.

What is Engine Knocking and Carbon Buildup?

Engine knocking, also known as detonation or pinging, is a condition that occurs when fuel in the engine’s combustion chamber ignites prematurely or unevenly. Instead of a smooth, controlled explosion, the air-fuel mixture detonates in bursts, causing a knocking or pinging sound. This irregular combustion puts excessive stress on engine parts and can lead to serious damage if not addressed.

One major cause of engine knocking is carbon buildup. Over time, combustion byproducts form deposits on internal components such as the pistons, valves, and cylinder walls. These deposits reduce the combustion chamber volume and can create hot spots that ignite the fuel mixture before the spark plug fires—leading to knocking.

Moreover, carbon buildup interferes with:

- Air-fuel mixture flow

- Heat dissipation

- Valve seating

- Sensor accuracy

As a result, the engine becomes inefficient, runs rough, and emits more pollutants. The longer carbon is allowed to accumulate, the more difficult it is to remove, and the greater the risk of long-term mechanical damage.

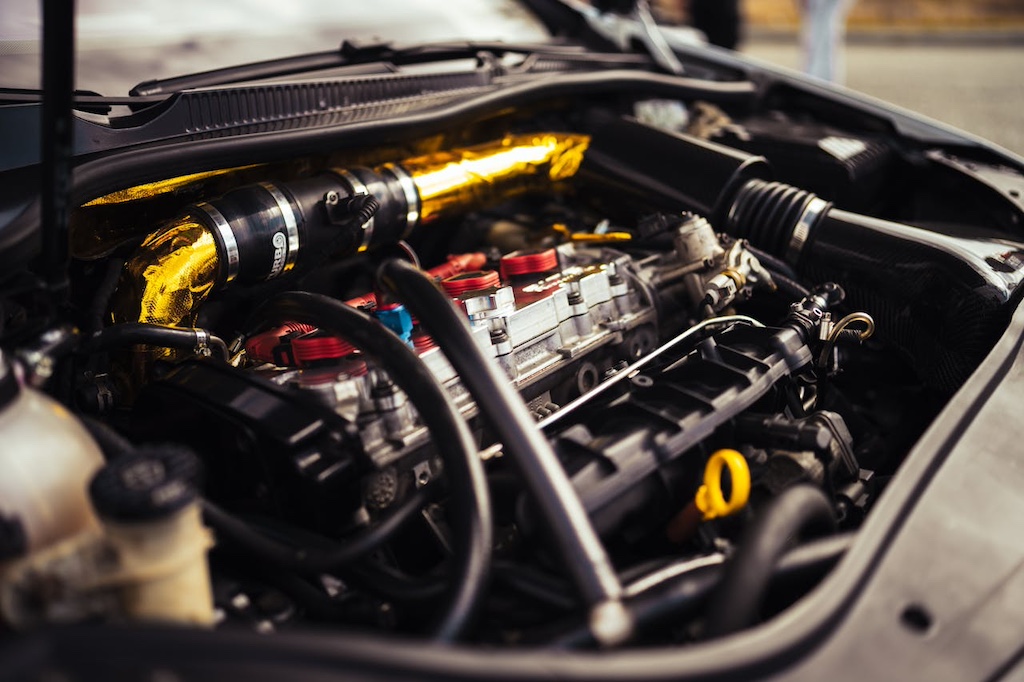

Application Areas for Carbon Remover: Combustion Chamber, Valves, Pistons, Intake Manifold

Carbon Remover is formulated to target and clean specific engine parts where carbon is most likely to accumulate. Its usage is applicable across multiple components, each playing a critical role in engine performance:

1. Combustion Chamber

The combustion chamber is the heart of the engine where fuel ignition occurs. Carbon deposits here disrupt the air-fuel ratio and ignition timing, leading directly to knocking. By applying Carbon Remover, these deposits can be safely broken down and flushed out, restoring the chamber to its optimal condition.

2. Intake Valves

Intake valves are responsible for letting the air-fuel mixture into the combustion chamber. When carbon accumulates on these valves, it restricts airflow, disturbs the mixing process, and triggers incomplete combustion. Regular cleaning with Carbon Remover ensures smoother airflow and improved engine breathing.

3. Pistons and Piston Rings

Carbon deposits on pistons can interfere with their smooth movement, leading to increased friction, blow-by (gas escaping the combustion chamber), and oil contamination. Carbon Remover helps dissolve these residues without the need for disassembly, maintaining optimal piston function.

4. Intake Manifold

The intake manifold distributes the air-fuel mixture to the cylinders. Over time, oily carbon sludge can coat the interior surfaces, restricting airflow and lowering engine efficiency. Carbon Remover cleans these surfaces, restoring proper air distribution and throttle response.

These applications are especially important in high-mileage engines, vehicles operating under heavy loads, or those using low-quality fuel, all of which accelerate carbon buildup.

The Importance of Regular Maintenance to Preserve Performance and Meet Emission Standards

Routine engine maintenance is more than just oil changes and air filters. In an era of strict emission regulations and advanced fuel systems, preventive carbon cleaning has become a necessity.

Why Regular Carbon Cleaning Matters:

- Improved Engine Performance: Clean engine components ensure proper combustion, delivering more consistent power and smoother operation.

- Better Fuel Efficiency: Removing carbon deposits improves fuel atomization and combustion, reducing fuel consumption.

- Lower Emissions: Carbon buildup contributes to increased CO₂, NOx, and hydrocarbon emissions. Using Carbon Remover helps reduce these pollutants and keeps your vehicle within legal emission limits.

- Extended Engine Life: Removing abrasive deposits reduces wear and tear, protecting engine components and minimizing repair costs.

- Avoiding Engine Knocking: As previously explained, a clean combustion system prevents the hot spots and imbalances that cause knocking.

Many modern engines, particularly those with direct injection systems, are more prone to carbon buildup and require more frequent cleaning. Incorporating Carbon Remover into your service schedule—whether as a fuel additive, intake spray, or engine flush—can be the difference between a reliable engine and one prone to costly failures.

Engine knocking and carbon buildup are more than minor nuisances—they are warning signs of inefficiency, mechanical wear, and rising emissions. Left untreated, they can degrade your engine’s performance, reduce its lifespan, and lead to expensive repairs or compliance issues.

Using Carbon Remover is a proactive step toward a cleaner, healthier engine. Whether applied to the combustion chamber, valves, pistons, or intake manifold, Carbon Remover helps eliminate the carbon deposits that cause knocking and emissions. When used as part of a regular maintenance program, it boosts engine performance, enhances fuel economy, and helps meet environmental regulations.

Read other Articles: Safe Usage Tips for Carbon Remover