Introduction

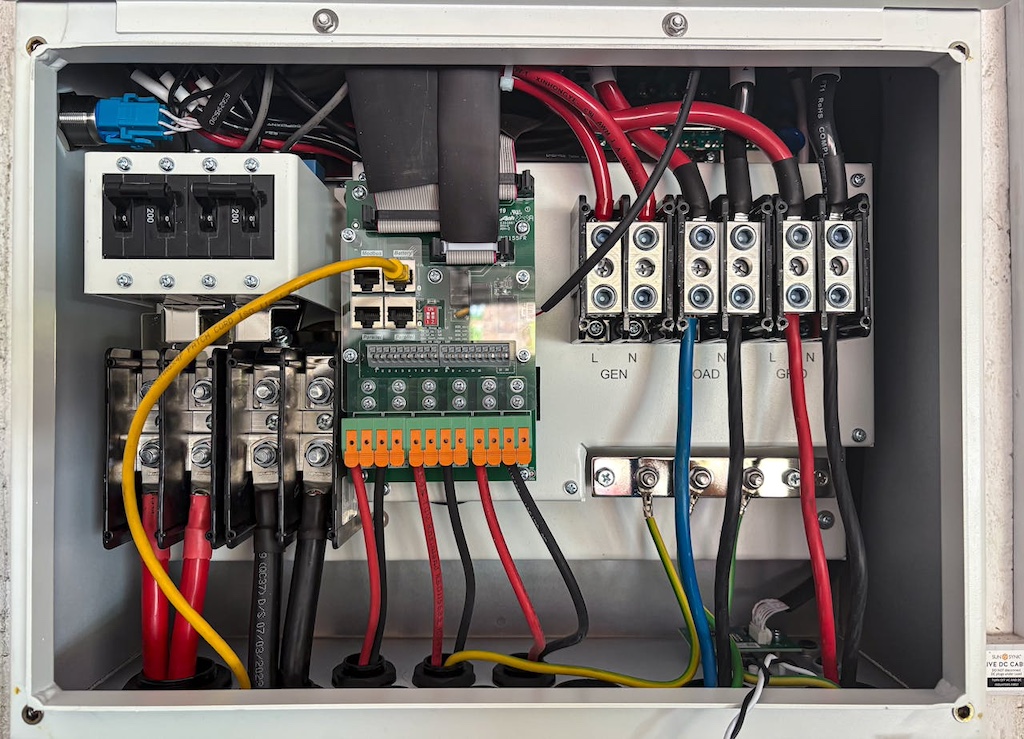

Electrical panels are the heart of power distribution systems in homes, commercial buildings, factories, and industrial sites. They regulate and channel electricity to various circuits and equipment, ensuring smooth operations and safety. However, despite their importance, electrical panels are often overlooked when it comes to routine maintenance, especially in terms of cleanliness. Over time, dust, oil, and dirt can accumulate inside these panels, increasing the risk of short circuits, component failure, and even fire hazards.

Maintaining a clean electrical environment is not just about appearance—it’s a critical part of operational safety and system longevity. Fortunately, modern solutions such as Electric Cleaner offer a safe and effective way to remove contaminants without damaging sensitive components. This article explains the dangers of panel contamination and its impact on electrical equipment. It also shows how Electric Cleaner helps with preventive maintenance.

The Dangers of Dust, Oil, and Dirt in Electrical Panels

Dust, oil residues, and industrial dirt are common in environments where electrical panels are located, whether in a dusty warehouse, an oil-fueled power plant, or a workshop with airborne particles. These contaminants may seem harmless at first, but their presence within an electrical panel can pose serious risks.

- Dust is often made up of tiny conductive particles. When it settles on circuit boards or terminals, it can cause arcing, overheating, or false connections.

- Oil from nearby machinery or airborne mist can coat surfaces, creating a sticky layer that traps more dust and moisture.

- Dirt and debris can clog ventilation, reducing airflow and leading to temperature spikes within the panel.

Together, these contaminants act as insulators or conductors in the wrong places, creating conditions ideal for electrical faults, short-circuits, or even explosions in extreme cases. In high-voltage or industrial setups, the cost of such faults can be catastrophic, both in terms of equipment damage and production downtime.

The Impact of Contamination on Panels and Electrical Equipment

Dirty panels don’t just pose fire and shock risks—they also significantly reduce the lifespan and performance of the electrical systems they support. Here’s how contamination affects key components:

- Circuit Breakers may trip more frequently or fail to respond when dust interferes with their mechanical or electrical function.

- Relays and contactors may stick or operate erratically due to grime buildup.

- Printed Circuit Boards (PCBs) inside control panels can corrode faster, short out, or suffer signal interference due to dust and moisture intrusion.

- Cooling fans and ventilation systems can become blocked, causing thermal stress that reduces the reliability of the entire system.

The result? Unexpected outages, frequent maintenance calls, and costly repairs. In regulated industries such as healthcare, manufacturing, or data centers, even a few minutes of downtime can lead to major losses or non-compliance issues.

That’s why keeping panels clean isn’t just about avoiding failure—it’s about ensuring consistent performance, reducing repair costs, and protecting both equipment and personnel from harm.

How Electric Cleaner Works to Clean Electrical Devices

Traditional cleaning methods, like using cloths or water-based solvents, can damage sensitive components, introduce moisture, or leave behind conductive residues. Electric Cleaner is specifically designed to clean electrical devices safely, effectively, and without leaving any trace.

Here’s how Electric Cleaner helps:

- Non-Conductive Formula: Electric Cleaners are formulated to be dielectric, meaning they do not conduct electricity. This makes them safe for live or sensitive circuits without causing short-circuits. Power shutdown is still recommended as best practice.

- Fast Evaporation: Most Electric Cleaners evaporate quickly without leaving any residue. This ensures the components are dry and ready for operation within minutes, minimizing downtime.

- Powerful Degreasing Ability: Electric Cleaners can remove layers of oil, grime, and industrial dust that standard tools cannot. This helps restore contact surfaces to their original conductive state and improves signal integrity.

- Precision Cleaning: The cleaner can be applied with pinpoint accuracy, reaching into small crevices, switches, terminal blocks, or PCB components without disassembly.

- Safe on Components: Unlike harsh chemicals, Electric Cleaners are designed to be gentle on plastics, rubber seals, and coated metals used in electrical equipment.

To use, simply turn off the power (when possible), spray the Electric Cleaner onto the dirty components or areas. Let the solution do its work, and allow it to evaporate. No scrubbing, no rinsing, and no residue left behind. It’s a quick, convenient, and reliable solution for both preventive and corrective maintenance.

The Importance of Electrical Panel Maintenance with an Electric Cleaner

Electrical panels are critical infrastructure in any facility, yet they are often neglected when it comes to regular cleaning and care. As dust, oil, and dirt accumulate, the risk of short circuits, equipment failure, and fire hazards increases significantly. These contaminants not only compromise safety but also degrade the performance and lifespan of your electrical equipment.

By incorporating Electric Cleaner into your maintenance routine, you can safely remove harmful residues, restore operational efficiency, and protect your electrical systems from unnecessary wear and breakdown. Its fast-drying, non-conductive formula ensures that cleaning is efficient, safe, and residue-free, making it an essential tool for anyone responsible for electrical safety and reliability.

Read other Articles: Characteristics of a Good Electric Cleaner