As engines continue to evolve and emission standards become more stringent, maintaining engine cleanliness is more critical than ever. Carbon remover products are essential tools for individuals and companies aiming to improve engine performance and extend machinery lifespan. They also support eco-friendly fuel systems like Diesel Exhaust Fluid (DEF) and AdBlue®. However, while carbon removers are powerful and effective, they often contain chemical ingredients that require careful handling. Misuse can result in harm to people, property, or the environment. This article provides safety tips for using a carbon remover, including understanding its function and the need for PPE. It also explains the importance of the Material Safety Data Sheet (MSDS) in ensuring responsible product usage.

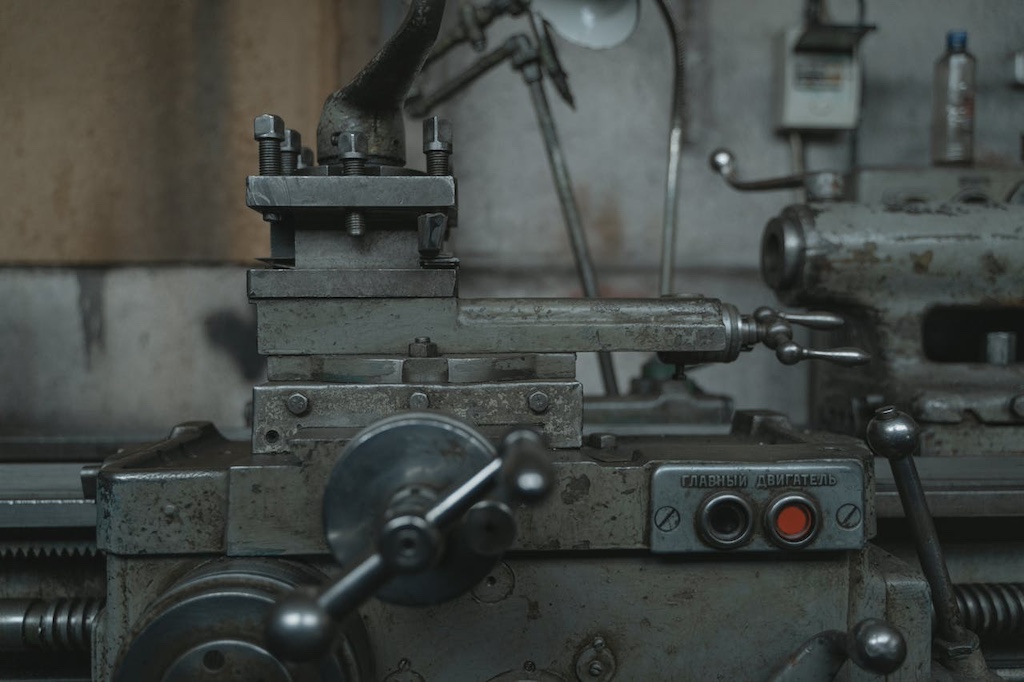

How a Carbon Remover Works

A carbon remover is a chemical solution designed to dissolve stubborn carbon buildup in engine components. It targets parts like pistons, valves, injectors, and combustion chambers. Carbon deposits form over time due to incomplete fuel combustion, oil contamination, or poor fuel quality. This is especially true in engines operating under heavy loads or stop-and-go conditions.

When applied, the carbon remover penetrates hardened carbon layers and breaks them down chemically. The softened substances can be wiped away, drained, or burned off during engine operation. Some products are added directly into the fuel system, while others are sprayed or poured onto the affected engine parts. The goal is to restore clean combustion, improve fuel efficiency, and reduce harmful emissions. This helps prevent long-term engine damage.

Because the active agents in carbon removers are often acidic, caustic, or solvent-based, they are highly effective but also potentially hazardous. This is why safe handling practices are not just recommended—they are essential.

The Importance of Using PPE or Hiring Professional Services

While carbon removers are incredibly useful, their chemical properties can pose health and safety risks if not handled correctly. Whether you’re using the product as a DIY solution or in an industrial setting, Personal Protective Equipment (PPE) is your first line of defense.

Essential PPE for Carbon Remover Use:

- Gloves: Chemical-resistant gloves (such as nitrile or neoprene) protect your skin from burns, irritation, or allergic reactions caused by direct contact.

- Safety Goggles or Face Shields: These shield your eyes from splashes, which can cause serious eye injuries or even temporary blindness.

- Respiratory Protection: If you’re using the product in an enclosed space, vapors and fumes can be harmful when inhaled. A suitable respirator or mask rated for chemical exposure is strongly advised.

- Protective Clothing: Long-sleeved shirts, aprons, and overalls can prevent skin exposure, especially in case of accidental spills or splashes.

In industrial environments or for more complex cleaning procedures, it’s often better to hire a certified professional. Trained technicians know the proper application techniques, are equipped with the right tools and gear, and understand how to minimize risk while maximizing results. This not only ensures a safer work process but also helps protect your equipment from improper use that could lead to corrosion or damage.

Why the MSDS (Material Safety Data Sheet) of the Product Matters

The Material Safety Data Sheet (MSDS)—also known as the Safety Data Sheet (SDS)—is a comprehensive document that accompanies every chemical product, including carbon removers. It provides crucial information for users, employers, and emergency personnel.

Key Reasons the MSDS is Essential:

- Detailed Hazard Information: The MSDS outlines chemical ingredients, their potential health effects, flammability, toxicity, and environmental hazards.

- Safe Handling Guidelines: Instructions on how to store, transport, and apply the product are specified, helping prevent accidents and misuse.

- Emergency Measures: In case of exposure, ingestion, or spillage, the MSDS provides first-aid steps, firefighting procedures, and cleanup techniques.

- PPE Recommendations: The document includes exact PPE requirements based on the product’s chemical composition and risk level.

- Disposal Instructions: Proper disposal methods are included to ensure environmental compliance and avoid fines or ecological harm.

For workplaces, keeping the MSDS readily accessible is a legal requirement in many countries. Even for personal use, reading the MSDS before applying the product can mean the difference between safe cleaning and a dangerous mishap. If a carbon remover doesn’t come with an MSDS or the data seems unclear, consider it a red flag—reputable manufacturers will always provide one.

Carbon remover is a powerful ally in the fight against engine carbon buildup. It restores efficiency, extends equipment life, and supports low-emission fuel systems like AdBlue® or DEF. But its chemical strength also demands respect. By understanding how carbon remover works, committing to the use of proper PPE, and carefully reviewing the MSDS, you can use these products safely and effectively.

Whether you’re a mechanic, a fleet operator, or a business owner committed to sustainable maintenance, adopting safe usage practices isn’t just smart—it’s essential. With the right precautions, Carbon Remover helps keep engines running clean and emissions low. It ensures efficient and responsible operations.

Read other Articles: Carbon Remover: Precision Solutions for Residue-Free Engines